The Future of Manufacturing with Cutting-Edge 3D Printing

The manufacturing industry has gone through various transformations over the years, but none have been as significant as the introduction of 3D printing. This technology has revolutionized the way things are designed and produced, making it possible to create complex shapes and parts that were once impossible to achieve using traditional manufacturing methods. The future of manufacturing looks bright with cutting-edge 3D printing, and here’s why…

The Advantages of 3D Printing

One of the biggest advantages of 3D printing is its ability to produce parts quickly and efficiently. Traditional manufacturing methods involve multiple steps, which can take days or even weeks to complete. With 3D printing, a part can be designed on a computer and printed within hours, eliminating the need for multiple steps in the production process.

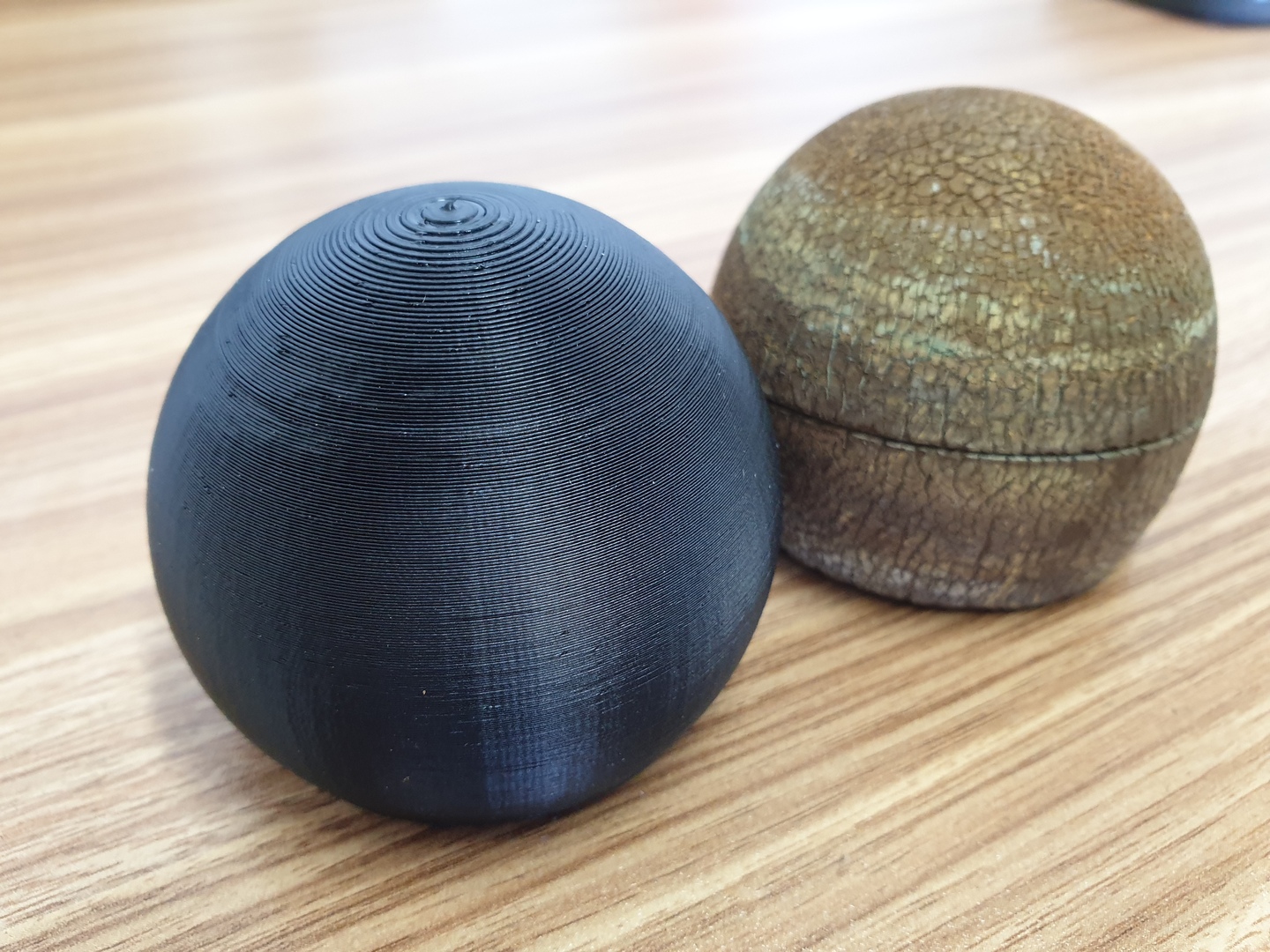

Another advantage of 3D printing is its ability to create complex shapes and geometries that are difficult or impossible to achieve using traditional manufacturing methods. This means that designers can create parts with intricate details and shapes without compromising on strength or durability.

The Impact on Manufacturing

The impact of 3D printing on manufacturing is significant. The technology has made it possible to produce parts on demand, reducing the need for large inventories and warehouses. This means that companies can save money on storage costs and reduce their environmental footprint by producing only what is needed.

Furthermore, 3D printing has made it possible for companies to customize products according to individual customer needs. This means that companies can offer personalized products without incurring additional costs, making it easier to meet customer demands.

The Future of 3D Printing

As technology continues to evolve, so will 3D printing. In the future, it is expected that 3D printers will become more affordable and accessible, making it easier for small businesses and individuals to take advantage of the technology.

Furthermore, advancements in materials science will make it possible to print parts using a wider range of materials, including metals and even human tissue. This opens up new possibilities for medical applications and personalized healthcare.

Conclusion

In conclusion, the future of manufacturing looks bright with cutting-edge 3D printing technology. With its ability to produce parts quickly and efficiently, create complex geometries, customize products according to individual customer needs, and reduce storage costs and environmental footprint, it’s no wonder why this technology is gaining popularity among manufacturers worldwide.

If you’re interested in learning more about 3D printing and how it can benefit your business or personal projects, be sure to check out our 3D Printing page. Our team of experts can help you navigate this exciting new world of manufacturing!

Contact us today!

If you would like more information on how Elite Engineering WA can help you with your next project please contact us for a quote or more information. Email sales@elitewa.com.au or Phone 1300 887 461

News

March 23, 2023

Share on: