3D Printing Perth

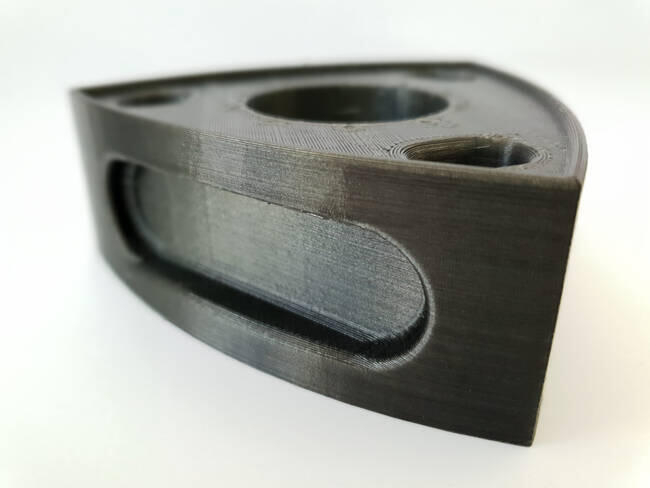

We are able to provide professional quality 3D printing services.

With a wealth of 3D Printing knowledge we offer not only 3D Printing services but also Design for Additive Manufacture, Material Selection and Research.

With our 3D printing services we can offer:

- 3D Prototyping

- Custom 3D Printing

- Professional Finish

- Rapid Turnaround

- Affordable Prices

- Large Build Volumes

- A massive range of colours and materials

- Advice on Material Selection

- Design for Additive Manufacture

With everyday that goes by there are new 3D Printing Materials added to the market, both in Metal 3D Printing and Plastic 3D Printing.

As we are a local 3D printing service we are happy to visit you for a consultation on the best 3D Printing material and process to suit your needs.

Elite Engineering WA are the experts in 3D Printing Perth. No matter how big or how small your 3D Printing requirement is we will be able to help.

Please contact us for a chat about how we can help with your 3D Printing requirements.

Design for Additive Manufacture

Great 3D Prints start with Great Designs.

To get the most out of 3D Printing like light weight high strength parts you need to either design or re-design your parts for the manufacturing process you will be using (3D Printing), it is called Design for Additive Manufacture.

Different 3D Printing processes have different strengths and weaknesses, Design for Additive Manufacture exploits these strengths and minimises the weaknesses to obtain an exceptional product as an output.

Most 3D Print failures with modern 3D Printers are caused in the design process. With knowledge of the 3D Printing strengths and weaknesses, Expert Design for Additive Manufacture skills and a Wealth of Experience we are able to help you go from initial concept to prototype/product in a very short time frame, days not weeks or months.

Design for Additive Manufacture allows you to optimise your product through:

- Part Consolidation - with 3D Printing you are able to consolidate multiple parts (that had to be split up because of the manufacturing process or complexity) into a single part.

- Complex Part Design - previously impossible parts are now possible with 3D Printing. Internal cavities, complex internal ports, etc, are now possible.

- Weight Reduction - 3D Printing is an additive process which means you have the option to add material only where it is required, which equals significant weight reductions

- Waste Reduction - Unlike subtractive manufacturing, additive manufacturing only uses the material required to produce the parts which cuts down on waste material. Which is both great for the environment but also reduces part cost.

Please contact us for a chat about how we can help with your Design for Additive Manufacturing requirements.

3D Printing Materials

Engineering Grade 3D Printing Materials

3D Printing has evolved from just printing toys and Yoda heads, there are some fantastic engineering grade materials on the market

Choosing the best material to suit your needs is something we can help with. 3D Printing Materials range from flexible urethane’s through to carbon fibre reinforced plastics through to Titanium and other 3D Printed Metals.

Some of the materials we are currently using are:

- Chopped Carbon Fibre reinforced PETG

- Chopped Carbon Fibre reinforced Nylon

- PETG

- Polycarbonate

- ABS

- PLA

If you would like more information on how Elite Engineering WA can help you with your next project please contact us for a quote or more information. Email sales@elitewa.com.au or Phone 1300 887 461

FAQS

Here are some frequently asked questions about 3D Printing:

3D printing, also known as additive manufacturing, is the process of creating a physical object from a digital model by adding material layer by layer until the final shape is achieved. The process typically involves the following steps:

- Creation of a 3D model using computer-aided design (CAD) software or 3D scanning technology.

- Preparation of the 3D model by slicing it into multiple thin layers using specialized software.

- Transfer of the sliced model to the 3D printer, which uses various materials such as plastic, metal, or even wood to create the object by depositing or curing material layer by layer.

- Post-processing of the printed object, which may involve removing supports, sanding or polishing, painting, or other finishing touches.

The three most important things to know about 3D printing are:

- 3D printing is an additive manufacturing process that creates objects layer by layer.

- A 3D model is required to start the printing process.

- Various materials can be used for 3D printing, including plastics, metals, and wood.

There are several advantages to 3D printing over traditional manufacturing methods. These include:

- Customization: 3D printing allows for the creation of unique, custom-made objects that are tailored to specific needs or requirements.

- Speed: 3D printing can be much faster than traditional manufacturing methods, especially for small-scale production runs.

- Cost-effectiveness: 3D printing can be more cost-effective for small-scale production runs, as it eliminates the need for expensive molds or tooling.

The three most important advantages of 3D printing are:

- Customization of objects to meet specific needs.

- Faster production times than traditional manufacturing methods.

- More cost-effective for small-scale production runs.

While 3D printing offers many benefits, there are also some limitations to consider. These include:

- Material limitations: While 3D printers can use a variety of materials, the selection is still more limited compared to traditional manufacturing methods.

- Size limitations: The size of the object that can be printed is limited by the size of the 3D printer bed.

- Quality limitations: The quality of the printed object may not be as high as that of a traditionally manufactured object, especially for more complex shapes or intricate details.

The three most important limitations of 3D printing are:

- Limited selection of materials compared to traditional manufacturing methods.

- Size limitations for the objects that can be printed.

- Quality limitations, particularly for complex shapes or intricate details.

3D printing is used in a wide range of industries and applications. Some common applications of 3D printing include:

- Rapid prototyping: 3D printing allows for the quick and cost-effective creation of prototypes, enabling designers to test and refine their designs before moving to full-scale production.

- Manufacturing: 3D printing can be used for small-scale manufacturing runs, particularly for products that require customization or have complex geometries.

- Medical and dental: 3D printing is increasingly being used in the medical and dental fields to create custom implants, prosthetics, and surgical tools.

The three most common applications of 3D printing are:

- Rapid prototyping

- Manufacturing

- Medical and dental applications